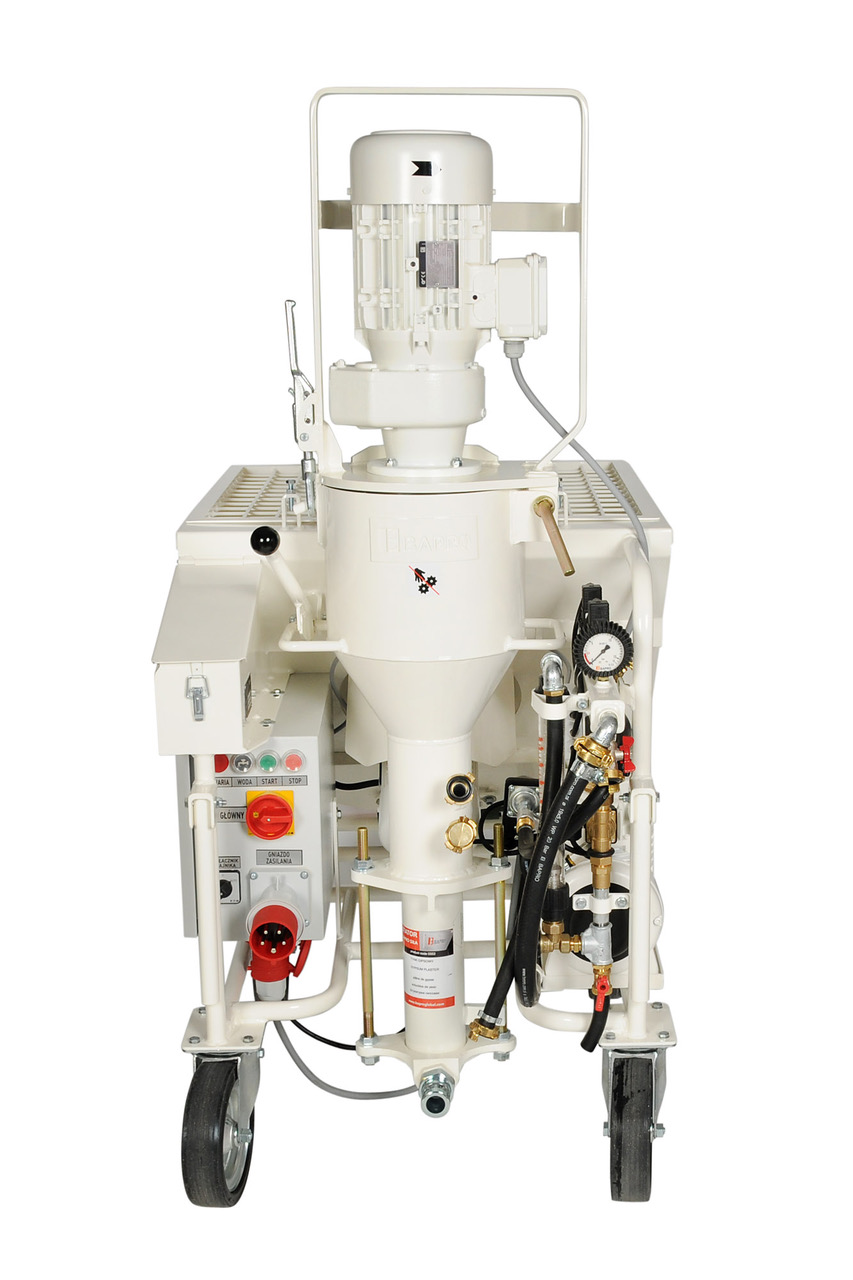

If you appreciate high quality and looking for an efficient machine you should thinking about purchase machine type BAPRO one 230V STRONG MAX. We recommend probably the best plastering machine in the World. This is an innovative machine on a global scale which is the only one based on a patented proprietary solution consisting of a variable work system. Until now, many numbers of construction works have been carried out manually or using several machines. To minimize costs and increasing work efficiency, we have developed BAPRO one 230V STRONG MAX. We can confidently say that this machine sets new standards in plastering machines. Unlike typical plastering machines, it allows you to expand the scope of services without focusing only on factory-dry mixed mixtures for machine use, in particular gypsum or cement-lime plasters, but also in addition to liquid mortars in buckets e.g. (facade plaster, liquid screeds, finishing coats or glue). Our solution also allows the use of the machine for traditional plastering with cementlime mortar mixed in a concrete mixer and then spraying.

Reviews

There are no reviews yet.